Innovative Approaches in Wood Industry

Dr. Sabit Tunçel Atanur Satır Doç. Dr. Zeki Candan

Abstract

For businesses to act in accordance with the developing technology will enable them to differentiate from their competitors with innovative approaches in a competitive environment. In addition to competitive elements such as cost, aesthetics, functionality, etc., all the innovative approaches of a business from design to final product are also an important mechanism in getting the edge over the competition.

Innovative thinking has different and important effects on the development of business models. Traditional revenue models involve unforeseen risks. For example, wrong and weak preferences that may occur in the parameters such as selection of job type and job site, determination of target group, pricing policy etc. can cause the related business model to fail. It is, however, possible to prevent financial losses by exhibiting the innovative approaches that minimize these risks.

In order businesses to survive, it has become essential to maximize their profitability because of the high-ranking competition as a result of the global economy. In this context, the businesses that operate efficiently are able to achieve the desired profit margins. Otherwise it has become nearly impossible for them to survive.

In the wood industry, the final products are produced by passing the raw material obtained from forest resources through various processes. Within all this complex structure, the businesses often suffer financial losses or cannot take huge leaps because of traditional habits. Apart from this, the handling of production processes and marketing the products with a new perspective form an important basis for the economic breakthroughs.

Within the framework of this academic research, the effects of the innovative methods and the transformations that these methods would bring in to the wood industry besides its traditional structure are examined.

Keywords: Innovative approach, Wood industry, Sectoral competition

1. Innovation Perception Of Enterprises

1.1. What is Innovation?

Innovation is an approach that encompasses all the processes carried out to develop new or improved products, services, or production methods and to make them commercially viable (Çetin).

Oslo Guide, a joint-publication of OECDO and Eurostat, and translated into Turkish by TÜBİTAK, describes “innovation” as follows: “An innovation is the execution of a new or significantly improved product (good or service), or a process, a new marketing method or a new organizational method in inter-business applications, workplace organization or external relations.” (Oslo Manual 2006). As can be understood from this definition, innovation cannot be isolated from any of an enterprise’s activities, in fact, it means an integrated approach covering an enterprise’s all activities.

Innovation is doable by turning new ideas and discoveries into commercial benefits for the sustainability of the enterprises. That is, innovation management is a process where the introduction of new ideas turns into financial gain (Taşkın 2014).

1.2. Innovation Requirement

The competitive conditions in which the enterprises operate are constantly changing with the influence of the environment and technology. Innovation and R&D in this changing environment is indispensable in terms of the development of an enterprise. Being constantly dynamic and in change-oriented activities in order to be at the top of a competition bring success to an enterprise. Certainly, being in search of innovation in business model and differentiating from other competitors bring efficiency and success (Karayılmazlar, Çabuk et al. 2006).

In enterprises which adopt traditional management approach, the expected change and innovation do not occur at desired level due to the management’s attitude. As a result, the enterprise lags behind its competitors over time and loses market share.

Enterprises are not able to increase productivity and quality without R&D and adding knowledge to processes. It is also not possible to increase the volume of their trades unless new products are developed that contain knowledge.

It is possible for enterprises to create higher added-value with people with a high level of knowledge and a high investigative personality. However, for enterprises it does not go further than low-cost and less intelligent labor employment since the goal is to produce low-cost products without added-value (Kavrakoğlu 2016).

The development and change in wood industry have preferred or transferred of what has been done until today. From now on, it is necessary to adopt “more creative production approach than imitationist one. For this, employees must be motivated, encouraged in creativity and innovation, and a productive environment needs to be established to improve innovation.” (Karayılmazlar, Çabuk et al. 2006).

2. Innovation Approach

2.1. Innovation and R&D Concepts

Innovation can be done in the total process cycle as well as in entire process and its sub-processes. Innovation should not be considered like R&D. One has to make an expense for the research to be carried out and consequently a new product or service can be created in accordance with information obtained. Innovation, however, can be done in every topic and in every field and the outcome that is achieved as a result of the change of a current method or process is also an innovation. The important thing at this point is whether innovation provides added-value and whether it creates plus-value to the enterprise. If answers to these questions are “yes”, it can be said that one is doing an innovative work.

According to the OECD Frascati manual, the definition of R&D is given as “R&D comprise creative and systematic work undertaken in order to increase the stock of knowledge -including knowledge of humankind, culture and society -and to devise new applications of available knowledge.” (Gök 2002).

2.2. Innovation Areas

Innovation can be applied to all processes of an enterprise, but these areas have been categorized in a close-approaches in the literature. The Oslo guide has been grouped under four titles to cover these areas.

a- Product Innovation: It is the introduction of a new or significantly improved product or service according to their current characteristics and intended use (Oslo Manual 2006). Here, the term of product has been used as to cover products and services. It includes innovative work to be done in anywhere of the entire flow from innovations to be done in the processes to innovations occurring during the use of end-consumers in the production of product or service. Innovation in the way of the deliverance of a product or service (i.e. in efficiency or use of capacity) can include the change in the current production method such as increasing the efficiency of the production using the same production model but new additional equipment or increasing the capacity using different production models.

b- Process Innovation: It is the application of a new or significantly improved production or delivery method (Karayılmazlar, Çabuk et al. 2006). With innovations to be done in the processes, the unit production time can be shortened, delivery costs can be reduced or innovations can be conceived to enhance quality with making significant differences for the costumers.

c- Marketing Innovation: It is a new marketing method that involves the important changes in the designing or packaging the product, the position of it in market, and presentation and pricing of it (Karayılmazlar, Çabuk et al. 2006). It can be thought as a way for an enterprise to enter new markets to increase the sales, to develop different marketing strategies or to develop new methods that can respond to customer demands more successfully.

d- Organizational Innovation: It is a new organizational method in the commercial application of an enterprise, in the workplace organization or in the external relations (Karayılmazlar, Çabuk et al. 2006). It is anticipated that the constitution of a new structure that has not been implemented before in the organizational structure and increasing the satisfactory of employees and customers within it.

In the classification of the innovation process of which the short descriptions and scopes are given above, the possible subheadings with the headings are shown in Fig. 1. It is divided into four main themes and each theme has been detailed thoroughly.

2.3. Interaction in Innovation

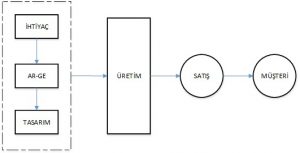

There are two different interactions that trigger the formation of innovation. The first is the innovation that is shaped by finding solutions to unmet needs and problems in current applications (Brem and Voigt 2009) This is called market-demanding innovation and market pull. A schematic diagram of how the market pull works is given in Fig. 2. The emergence of LPG-powered automobiles is a good example for this. High fuel prices, especially in Turkey, have led the consumers to more affordable fuels. Then, LPG products which can be installed to the vehicles afterward have emerged.

As known, cars are out of factory having gasoline or diesel-powered engines. The same engine is put into operation by the installation of LPG tank and equipment particularly for pulling the cost of gasoline down.

The second is the innovation method which is developed with R&D studies and carried out with the use of new technology or new materials and brings more effective solutions along with. This is called the technology push because of the development of the technology. The best example of this type of innovation that is formed by the technology push and schematically shown in Fig. 3 is smart phones.

An enterprise’s innovation capacity is closely related to its competitiveness. The strength of competitiveness and innovation of enterprises depend on the size of the enterprise and the orientation to exportation (Cao 2004). According to this definition, as a result of the aforementioned processes of innovation, the enforced improvement by the demand from the market or the development of technology becomes important in terms of the development and continuity for an enterprise. The failure of an enterprise in developing an innovation lags it behind its competitors which would result an enterprise to collapse in future. For instance, it is known that some of globally-known companies in 90’s have become collapsed today.

3. Innovation In Furniture Manufacturing Operation

The furniture industry in Turkey is predominantly occupied by workshops and small-scale enterprises, which adopt traditional methods. In recent years, however, the number of medium and large-scale enterprises has started to increase rapidly. According to SGK data of 2014, the furniture industry is in the 4th place with 20.867 enterprises in the manufacturing industry. It is in the 7th place with 165,118 employees. At the end of 2014, it is estimated that the worth of the production of the furniture industry is 19 billion USD and of the consumption is 14 billion USD in Turkey (Orta Anadolu İhracatçı Birlikleri Genel Sekreterliği 2016).

The European Union Furniture Industry has undergone significant changes in recent years. The main factors that trigger this change are the desire of the exporter to enhance the quality, design and innovation value (European Commission Furniture Industry).

In addition to the increasing globalization and digitization of markets, relying on only innovation and design are not enough to protect the intellectual property rights. Rapid and strong research and innovation also require financial support. In this context, SMEs do not have sufficient financial strength and hence the level of innovation does not develop at the same rate.

As a result of being in a search of a solution to the demands and problems in the furniture industry, hinges with brakes on cabinet doors, which can be described as an innovation pull, can be given as an example. The brake system that was firstly installed to the cabinet doors as a separate apparatus can be produced integrated with the hinges in parallel with the technological improvement. Also, the examples to the innovation push in the furniture industry are laminate flooring and sofa beds, where a sofa have a mechanism which turns into a bed. Use of solid wood in the production of flooring for a long period of time has caused resource shortage and led to new search and together with developing material and processing techniques, HDF (high density fiberboard), which is a wood-based material, and laminated flooring materials of which upper side has wood-like patterns have been produced. Particularly in places where the use of wood is requested, laminated flooring -laminating wooden sheets to counter material- has been brought into service.

In 2015, as a result of the study initiated to solve the capacity problem experienced in the CNC surface finishing machine in an office furniture producing enterprise, to which consultancy services are provided, machine capacity is increased by 100% and unit processing time is shortened with the novel approach in the production process. In this study, every stage of the current business process was examined to reach the solution and brainstorming has been done with the engineers in the enterprise on which phase of the process the improvement can be done. At the end of the study, with a developed method the number of parts processed by the machine in one operation was increased to two and the capacity increased twice. In Fig. 4, the current situation and the result after the innovation are shown schematically.

Innovation here has emerged with the enforcement of conditions and is a good example for the innovation pull.

Another example for the innovation in the Turkish Furniture Industry in recent years is “smart bed” products. Various smart beds were developed under the brand “MedBed” and several patent applications were made by Zeki Candan, Faculty Member of Istanbul University Forest Products Engineering Department and Özkan Ocak, Forest Products Engineer. The body temperature of the person lying on the bed, especially the infants, is detected and when the emergency is arisen, the situation is automatically transmitted to the relatives and doctor of the person lying and emergency medical service (Smart Bed: “MedBed” 2015).

Actually, there are many innovations that have been done in wood sector with the enforcement of the conditions. However, because of the lack of recording and that the concept of innovation is not fully known in the sector, innovations are not emerged or neither attributed so.

3.1. Meaning of Innovation in Furniture Industry

The sector closely follows the development of machinery park by importing the technology. However, it is a disadvantage that the number of enterprises aiming to improve by investing only in machinery is high. In fact, it shows that the industry cannot provide real development. One of the most important deficits of the furniture industry is the slow pace of work on managerial structuring. In fact, this shows that the industry has not developed fully. One of the most important deficiency of the furniture industry is the slow pace of work on managerial structure. Particularly investment on white-collar personnel is extremely low and employment of engineer is not sufficient. This also affects the work or analysis that can be done on innovation.

Today, there are many furniture enterprises that can be said large-scale in terms of their structures. When these companies are examined, it seems that managing some of these enterprises as a large-scale workshop leads to the formation of idle capacity. However, unnecessary machinery investment can be prevented by using the available capacity efficiently. The most important work to be done for this is the establishment of managerial infrastructure.

The flaws in the establishment of the concept of innovation in the industry and having lower R&D investments of the enterprises than that of in UN countries are caused by this gap. It is seen that in the furniture sector, where engineering studies should be predominant, the enterprises still work on the initiative of the chief. The enterprises in furniture industry need to carry out the operations with a professional engineering approach. Otherwise, the intensive competition around the world is expected to continue to take the enterprises down.

4. Conclusion And Recommendations

The opportunities of innovation management available to industry needs to be analyzed and evaluated correctly. Adopting an innovative approach to stand out of the competition should be the management’s priority. In this regard, as stated in the research done by Taşkın (Taşkın 2014), the lack of training of the employees needs to be eliminated to be able to seize the innovation approach in the furniture production enterprises.

As mentioned above, managerial structures must be rearranged and shaped according to modern management approach so that enterprises can successfully carry out the innovative work.

Leaving the classical management approach behind and moving towards a more participatory structure will spread innovative approach to the basis.

In order to ensure full participation in the innovation approach, the enterprise management should be open to new ideas. In addition, a functioning proposal and performance evaluation system will stimulate employee motivation and innovative approach.

full paper has to be submitted electronically via the website of the conference management system (http://cmt3.research.microsoft.com/ORENKO2018) by July 15th 2018.

5. Acknowledgements

The authors thank Chamber of Forest Engineers Istanbul Branch and Istanbul University-Cerrahpaşa for supporting this study.

5846 sayılı yasa gereği lütfen gerektiği gibi kaynak göstermeden alıntı yapmayınız.!

Bu yayın ORENKO 2018 Uluslararası Orman Ürünleri Kongresinde (The International Forest Products Congress) Bildiri olarak sunulmuştur. 26-29 Eylül 2018

References

Baltalar H. (2006). Kurumsal İnovasyon ve İnovasyonun Kurumsallaşması, Mobilya Sanayinde İnovasyon Uygulamaları Bildiri Kitabı, Eskişehir, p. Brem A. and Voigt K. (2009). Integration of market pull and technology push in the corporate front end and innovation management-Insights from the German software industry, Technovation, 29(5): p. 351-367. Cao X. (2004). Innovation in China's furniture industry, Oregon, Oregon State University. Çetin G. İnovasyon Nedir? (2017). Accessed 02.07.2017, http://www.guvencetin.com/inovasyon/. European Commission Furniture Industry. (2017). Accessed 17.07.2017, https://ec.europa.eu/growth/sectors/raw-materials/industries/forest-based/furniture_en. Gök. A. (2002). Frascati Kılavuzu Işığında Ar-Ge, TÜBİTAK, Ankara. Işık Ö. and Satı E. (2017). İnovasyon ve Marka Yönetimi Etkileşimi: Mobilya Sektöründe MOSDER Üyesi Firmalara Yönelik Bir Araştırma, Akademik Bakış Dergisi, 38, Accessed 20.07.2017. Karayılmazlar S. et al. (2006). İnovasyon Kavramına Bir Bakış; Türkiye’de İnovasyon, Mobilya Sanayinde İnovasyon Uygulamaları Bildiri Kitabı, Eskişehir, p. Kavrakoğlu İ. (2016). Yönetimde Devrimin Rehberi İnovasyon, İstanbul, Alteo Yayıncılık, p. 101-102. Orta Anadolu İhracatçı Birlikleri Genel Sekreterliği. (2016). Mobilya Sektör Raporu, Ankara. Oslo Manual. (2006). Yenilik Verilerinin Toplanması ve Yorumlanması İçin İlkeler, OECD, Avrupa Birliği. Smart Bed: "MedBed". (2015). Accessed 14.08.2017, http://orman.istanbul.edu.tr/?p=11391. Taşkın E. (2014). Mobilya Sanayi İşletmelerinde Yenilik Yönetimi ve Süreç Yenilikçiliği İncelemesi, 14. Üretim Araştırmaları Sempozyumu Bildiri Kitabı, İstanbul, p. 223-234. Tunçel S. (2017). Üretim Sistemlerinde Bütünleşik Yapı ve İnovasyon, Accessed 20.07.2017, www.sabittuncel.com. Yavuz Ç. (2010). İşletmelerde İnovasyon-Performans İlişkisinin İncelenmesine Dönük Bir Çalışma, Girişimcilik ve Kalkınma Dergisi: p. 144-173.